Mining & Trade News

Malawi Online News

Top Stories

Mining

Lotus moves towards Kayelekera uranium production with first feed into crushing circuit and SAG mill

August 01, 2025 / Admin

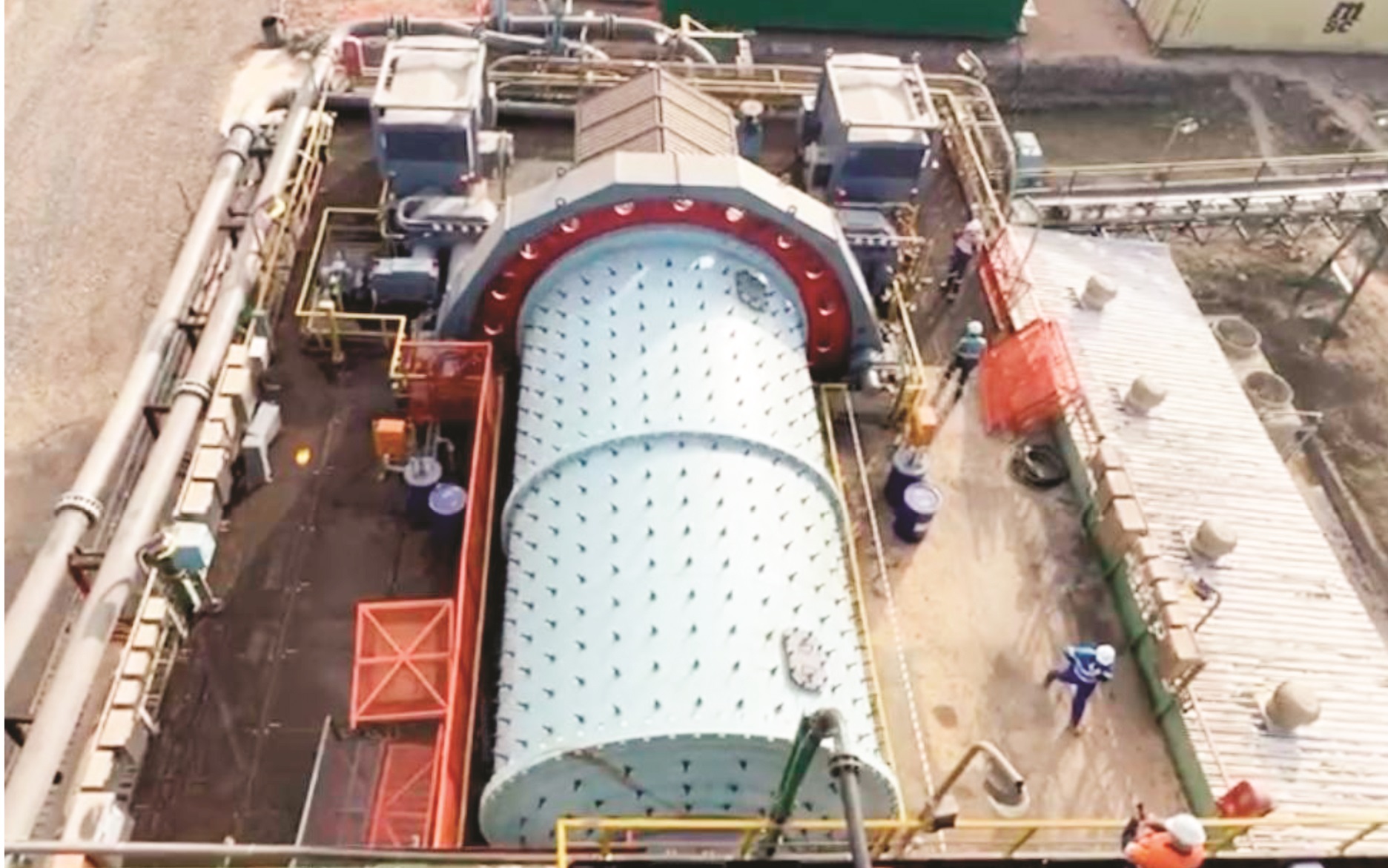

SAG mill refurbishment completed

Lotus Resources Limited (ASX: LOT, OTCQX: LTSRF) (Lotus or the Company) is pleased to provide an update on its Kayelekera Uranium Project in Malawi (Kayelekera or Project), as process plant refurbishment work nears completion ahead of first product this quarter.

HIGHLIGHTS

• Kayelekera SAG mill refurbishment completed, grinding media loaded and mill restart achieved

• Hot commissioning of crushing, grinding, pre-leach and leach areas underway

• Elution, precipitation, drying and packaging circuit commissioning underway, ahead of first uranium oxide (U3O8) product this quarter

• Lotus remains fully funded with A$77.3m cash at the end of June (unaudited), and no debt drawn .

Lotus Managing Director Greg Bittar commented: “Following the completion of extensive mill refurbishment, alignment and grinding media loading, we have restarted the Kayelekera mill. With the mill being such a critical aspect of the processing plant refurbishment, achieving its restart is a terrific milestone ahead of production at Kayelekera.

Whilst in Malawi for the mill restart, we updated the Government of Malawi, including the Ministry of Mining, on restart plans and the steps towards production this quarter.

We are currently feeding mineralised waste through Kayelekera’s mill as we verify its performance before transitioning to feeding in ore. With first ore through the mill, the restart of production at Kayelekera is on track for this quarter.

PROCESSING PLANT HOT COMMISSIONING, MILL REFURBISHMENT COMPLETE AND RESTARTED

The Kayelekera processing plant is now undergoing hot commissioning, which involves initially feeding the plant with mineralised waste before moving to ore. The plant will run on mineralised waste until the correct densities are achieved in the leach and resin in pulp circuits. Following this, the feed will be changed to ore while reagents are added to start leaching the uranium. Commissioning of the elution, precipitation and packaging and drying areas is underway, with first uranium to be produced this quarter as planned.